Alpma Equipment

Your partner for all your cheese-making requirements. We have over 50 years of experience in the planning and manufacture of efficient production plants for the production of diverse varieties of cheese. The principle of continuous curd processing with a coagulator was developed and optimized by us. We work together closely with you to deliver a plant which allows you to produce the variety of cheese you want with all its unique regional characteristics. At the same time ALPMA installations enable your cheese-making operations to achieve maximum yield with optimum flexibility. Our hygienically built machines permit you as an ALPMA customer to meet the highest requirements for bacteriologically perfect products. Moreover, our control systems offer you clear and simple plant operation, e.g. inputting pre-set recipes and menus.

Bar/Block Cutting

|

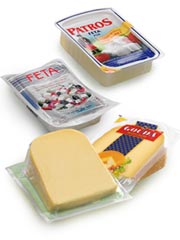

Small things from great. How does a great cheese cartwheel get into a small shopping basket? By cutting. Giant cheeses such as Emmental, alpine cheeses and Euroblocks are first divided into bars, then sent to CUT machines where they are soon reduced to small portions. The fully automatic process makes light work of everything. CUT machines can be used individually or integrated into lines. |

|

CUT 27 – Bar cutter for the automatic feeding of downstream cutting machines. The blocks are measured and individually divided into bars |

Cutting Round Cheese

Portioning

Modules for Lines

|

Modules for Slicing and Portioning Lines. Whether a cheese cutting line works economically is already decided at the block pre-cutting stage. The exact pre-cutting into bars of, for example, a film-ripened Gouda is essential for its successful processing in subsequent steps, be it cutting into pieces or slices. For a high degree of line automation ALPMA can supply you with various elements such as segment separating and grouping modules, bar magazines, storage units and turning systems. |

|

BTS 600 – Flexible block dividing system of modular design. For automatic cutting, turning and grouping operations according to requirements. |

|

CUT 27 – Bar cutter for the automatic feeding of downstream cutting machines. The blocks are measured and individually cut into bars. |

|

SB 230/12 – The dynamic buffering belt ensures the correct synchronization between the cutting machine and the continuous type packaging machine. |

|

RM – This bar magazine is the optimum storage unit for placement in front of any piece cutter or slicer. Differences in height between the block divider and piece cutter/slicer are taken in its stride. |

|

VESTOR II/S – The vertical buffering system with as many as 40 storage places can be used to synchronize any cutting line with a downstream bag packaging machine. |

|

TURN II/S with taring station – The logical conclusion to every slicer. The portions which are cut in a double shaft can be separated, turned and aligned before being forwarded to the downstream buffering and packaging machines. And the TURN II/S also tares products with the wrong weight – simultaneously in a single work step. |

|

TS B/150 – This taring belt system performs the re-taring for you so that no cheese is. |

Loaders

|

Loaders for Thermoforming Machines. Cutting and packing in one deep-draw packing machine. The two operations are usually separated by the manual work of loading, that costs you time and money and can even jeopardize the quality of your product. This gap in the process is closed by the CUT 25/M automatic high-performance piece cutter, the SC 150 segment cutter and the ER 10 automatic loader. After the portions are cut they are loaded fully automatically into the deep-drawing packaging machine. |

|

CUT 25/M and ER 10 – To obtain the best possible output we combine the cutting machine with a fully automatic synchronizing system that ensures the non-stop feeding of products to your deep-draw machine. |

|

SC 150 and ER 10 – The SC 150 automatic high-performance cutter cuts segments out of round cheeses with a diameter of up to 420 mm and separates the segments automatically. As many as 40 product types can be saved in a product type memory. The individual portions are then grouped, aligned and inserted directly in a deep-draw machine by the ER 10. |